In late January I ordered another cool fiber processing tool but it arrived around the time my baby cat passed away, so it took me awhile to get around to use it. I’ve always seen a hackle as a tool for blending fleece & fiber, and since I own a drum carder, poo-poo’d investing in one.

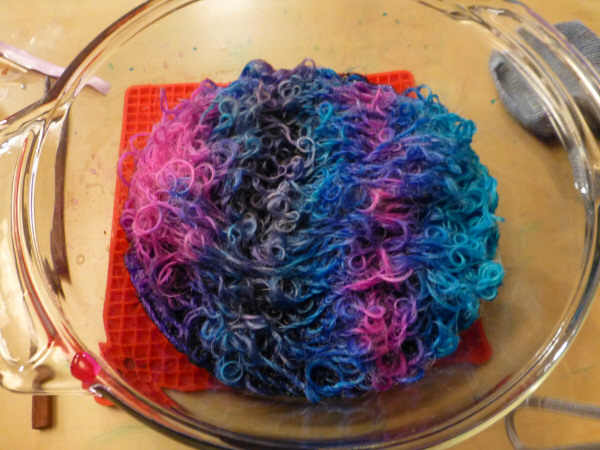

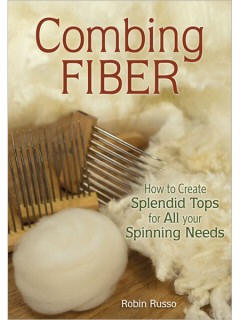

Then it occured to me one day that a hackle could make my life so much easier when it comes to combing fleece top. A drum carder is great for blending and making your fleece & fiber somewhat smooth, but it won’t remove all the noils or tiny gnarly bits nor is the fleece/fiber guaranteed to be lined completely straight like it would be if combed. This texture has merit for spinning, particularly chunky or woolen yarn. Of course I do like to spin a textured art yarn as well. For certain fleece that I hand process I prefer them to be smooth – like merino for instance. I love a nice, smooth, merino top. Plus I get the added bonus of felting with the leftovers. I love my St. Blaise combs, but there is only so much you can comb at once. With a hackles, I can load a larger amount of fleece, then comb it out with my combs.

I’m still working out my process with the hackle, but what I find is that I can load the uncombed merino onto the hackles, then comb with just one comb: added bonus is this is so much easier on my neck/shoulders/back. The hackle is clamped to the table, so instead of motion with two of my arms, I only need to used one arm.

This merino is pretty rough so I will comb as much will fit onto the comb, then finish it by hand combing with both combs, then pulling a small top. After the top is pulled the process repeats: back for more fleece from the hackle, combing out, and so on. This makes the process so much easier! I was amazed how fast I went through the fleece – it cuts the time in half, at least, not to mention it really saves my body from the wear and tear which is the biggest advantage. I love to work with my hands, whether it be jewelry making, paper crafting, fiber washing, dyeing, combing or spinning, but it does wreak havoc on my muscles and tendons so any tool which makes it go easier is worth it to invest in.

A Hackle is mostly used for blending and I have yet to try that. You can pull a nice long roving off of it rather than the little top I pull from my combs and coil into a nest. I purchased my hackle from Gemini Fibers here in Canada, and I appreciate that they are handcrafted in Ontario.